Back

Asset Management & Operational Strategy

Asset Inspection Workflow to Optimize Asset Health & Safety

Tuesday, May 7, 2024

11:45 AM – 12:00 PM CT

Jared Westrem

Global Principal of Asset Data Management

Thread

4200 James Ray Drive, North Dakota

Poster Presenter(s)

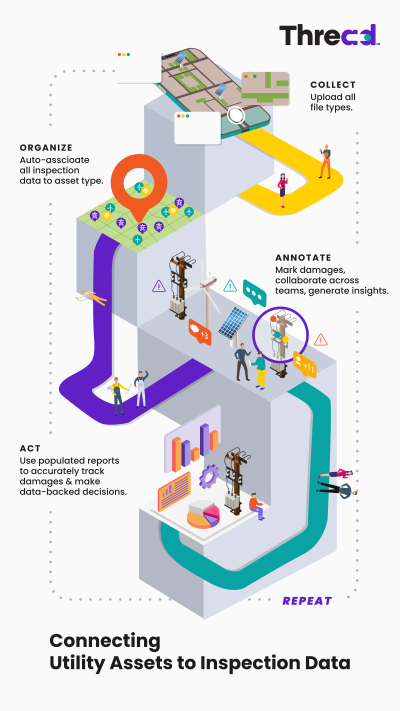

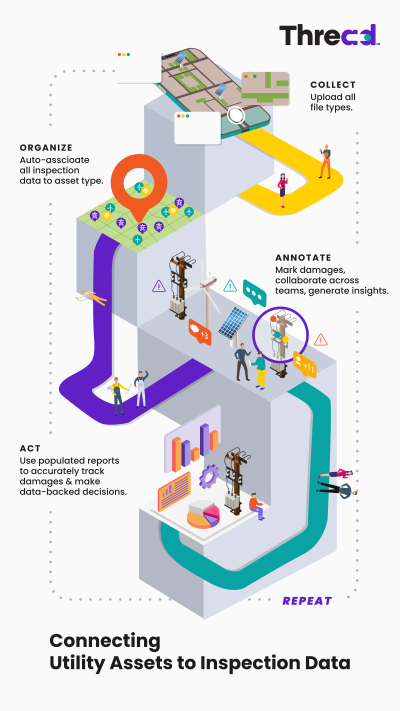

Presentation Description: Asset inspection automation has revolutionized how businesses operate, delivering greater efficiency, productivity, and cost savings. Data from asset inspections can be analyzed to provide efficiency and health estimates to guide maintenance and repair. Inspection workflows start with a request for data targeting specific equipment in the field. Using the asset location and contextual information, data can be organized and managed automatically. Using photos, drones, helicopters, or really any other digital source data, lineman, can perform inspections that automatically tie the collection to the request. Hands-off data management removes the burden from the inspection operator and reduces the potential for human error in the data generation process.

Whether the data is collected using optical imagery, thermal sensors, or LiDAR, the workflow for asset inspections remains the same: plan data collection, authorization for flight, data capture, data contextualization, calculate efficiency and asset health, and results dissemination. This workflow can be implemented regardless of what asset needs inspecting.

Despite the obvious benefits, many enterprises struggle to leverage the full potential of automation due to the complexity of integrating various systems and processes.

Whether the data is collected using optical imagery, thermal sensors, or LiDAR, the workflow for asset inspections remains the same: plan data collection, authorization for flight, data capture, data contextualization, calculate efficiency and asset health, and results dissemination. This workflow can be implemented regardless of what asset needs inspecting.

Despite the obvious benefits, many enterprises struggle to leverage the full potential of automation due to the complexity of integrating various systems and processes.

.png)

.jpg)

.png)

.png)