Back

Emerging Technology

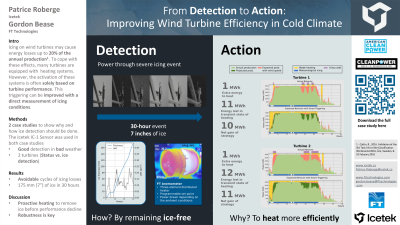

From Detection to Action: Improving Wind Turbine Efficiency in Cold Climate

Tuesday, May 7, 2024

3:55 PM – 4:10 PM CT

Patrice Roberge (he/him/his)

Lead data scientist

Icetek

Quebec, Quebec, Canada

Poster Presenter(s)

Presentation Description: Operating wind turbines in cold climates poses unique challenges compared to milder regions, particularly regarding the formation of ice on turbine blades, leading to a significant drop in energy production. This poster explores the issue of icing, with a specific focus on the effectiveness of ice sensors, such as the Icetek IC-1, in enhancing turbine operation. The poster thoroughly examines the IC-1 sensor's functionality and its seamless integration into wind turbines for real-time monitoring. A case study illustrates the successful increase in energy production by promptly identifying icing conditions to activate an anti-icing solution. The IC-1 detected ice significantly earlier than the turbine's icing code which proves to be critical for preheating the blades, a critical factor in eliminating ice efficiently.

Two crucial factors for effective ice detection on wind turbines are underscored: robustness and sensitivity. Robustness involves designing the sensor to withstand wind turbine conditions and using sturdy components such as the FT wind sensor. Numerous instances were observed where other sensor types failed to eliminate ice or broke during the first winter. With over 10 years of field experience, the IC-1 sensor has succeeded in some of the world's harshest icing environments. Sensitivity is vital for timely decision-making during icing events. The IC-1 combines patented thermal ice probes, precise wind measurement by the FT wind sensor, and meteorological data for high sensitivity. This robustness and sensitivity of the sensor are key components to achieve good results for successfully optimizing blade heating solutions or pausing turbines during icing events on those without blade heating to reduce ice accretion.

Two crucial factors for effective ice detection on wind turbines are underscored: robustness and sensitivity. Robustness involves designing the sensor to withstand wind turbine conditions and using sturdy components such as the FT wind sensor. Numerous instances were observed where other sensor types failed to eliminate ice or broke during the first winter. With over 10 years of field experience, the IC-1 sensor has succeeded in some of the world's harshest icing environments. Sensitivity is vital for timely decision-making during icing events. The IC-1 combines patented thermal ice probes, precise wind measurement by the FT wind sensor, and meteorological data for high sensitivity. This robustness and sensitivity of the sensor are key components to achieve good results for successfully optimizing blade heating solutions or pausing turbines during icing events on those without blade heating to reduce ice accretion.

.png)

.jpg)

.png)

.png)